- Home

- Case studies

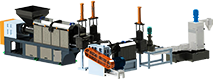

- Plastic Recycling Granulator in Japan

Through the introduction of an old customer, a customer from the plastic processing industry in Japan told us that he wanted to build a plastic recycling granulator on June 10, 2017. The customer wanted to produce ABS materials with an output of 300kg/h. Besides, the voltage in Japan is 200V. Considering that Japan plays more attention to environmental protection, the discharge of exhaust gas and waste water in workshop is forbidden. Thus, HaoSu customized the following solutions based on customer requirements and the conditions in Japan:

- A water cooling extruder granulator line was customized with an output of 300kg per hour.

- A special motor and special electrical equipment for 200V are equipped to this plastic processing line.

- Exhaust gas cleaning equipment is equipped for the gathering and centralized processing of exhaust gas generated in heating process to meet the emission standards.

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com