- Home

- products

products

HaoSu is a professional manufacturer of plastic recycling plant machines, which can process various waste plastics to produce plastic granules that can then be recycled. These granules can be used to manufacture plastic bottles, packaging films and other plastic products. Plastic recycling not only solves plastic pollution but provides us with affordable raw materials for new products.

HaoSu provides all kinds of plastic recycling machines, including recycling plastic shredding and cutting machinery, plastic recycling washing and cleaning machine, plastic recycling drying equipment, plastic extruder machines and so on. These machines can be configured into specialized plastic recycling lines to satisfy the production demands from different clients.

-

- Plastic Recycling System

-

- Whether you need to recycle waste plastic film, pipe, bottles, or agricultural waste, HS Machine offers an extensive range of custom plastic recycling systems to meet each of your needs.

Haosu will design and manufacture a complete plastic recycling system, including washing, drying, and separating for a highly effective recycling process of used and contaminated plastic waste.

-

- Pulverizing System

- Shredders, pulverizer, and crushers ensure plastic material size reduction during the plastic recycling process.

Haosu offers a wide variety of size reduction shredders/pulverizers for recycled plastics. Our shredders/pulverizers are capable of handling low volumes for laboratories or small plants, as well as medium and high-volume processes in industrial recycling plants.

-

- Pelletizing System

- HS offers an extensive array of custom extrusion and pelletizing equipment to meet a variety of customer needs to produce high-quality, uniform pellets. Whether it is strand pelletizing or water ring pelletizing, complete systems or individual components, each of our pelletizing solutions is tailored to unique customer requirements.

-

- Screw Extruder

- Two plastic extruder machines are traditionally equipped in a waste plastic recycling line: a main plastic extruder and an auxiliary extruder. The main extruder melts and extrudes plastics, whereas the auxiliary extruder is used to re-extrude materials before pulling the melted plastic into strips and prevent the risk of extruded materials not meeting granulation requirements.

-

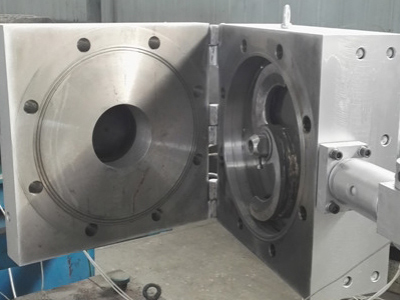

- Screen Changer (Melt Filter)

- The plastic extrusion filter system is paired with specific plastic extrusion equipment to filter our extruded materials during the plastic recycling process. This guarantees the quality of all plastic granules produced. We offer hydraulic continuous melt filters and continuous screen changers for customers to choose from.

-

- Strand Pelletizer

- The silent plastic granule cutter uses 23 rotor cutters to cut granules after the extruding and sand pelletizing processes. It is suitable for cutting PP, PE, PA and other plastics. The granule cutter features a cutting capacity of 300 to 60kg/hour, and its rotor cutters are chain driven for cutting. Compared to a traditional gear drive mode, there is very little wear, the service life has been extended, and features a low noise performance, thus reducing noise pollution.

-

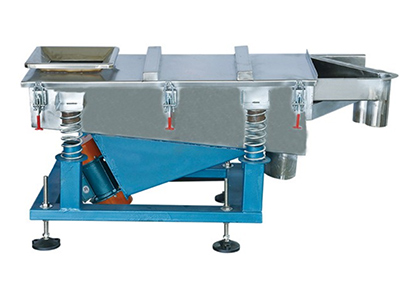

- Vibrating Screening Unit

- Plastic plant vibrating screens are used to screen plastic granules during the plastic recycling process. This screen filters out any impurities and powder mixed with the granules to ensure the granules are uniform. This vibrating screen requires an exceptionally lower power consumption of only 250W in its motor. In addition, this screen features a low noise operation, which in turn facilitates a comfortable production environment.

-

- Electric Control Cabinet

- Plastic plant electric control cabinets act as the “brain” of the plastic recycling line. Users control all equipment operation on the recycling line using switches in the electric control cabinet. It is a complete control system that includes the transducer, AC contactor, switch, PLC, and other equipment.

To provide customers with quality plastic recycling plant machines, HaoSu utilizes over 30 CNC machining centers for equipment production. The screws of our machines are all independently researched and developed and manufactured using 38crMoAL as its hardness reaches hv850-950, capable of machining many types of plastic wastes. Besides, this kind of screw has long life span and helps to increase the output of plastic recycling lines. Our company can design plastic recycling lines and offer the related plastic recycling plant machines following your demands.

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com