- Home

- products

- Pelletizing System

- Twin Screw Pelletizing

Twin Screw Pelletizing System

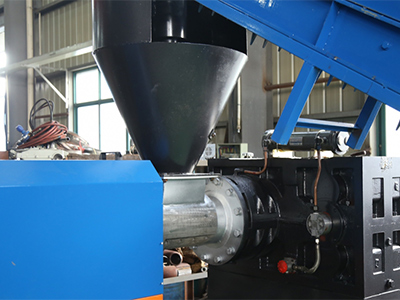

To increase output capacity and improve pellet quality, Haosu designs and manufactures twin screw pelletizers for processing a wide variety of plastic materials such as plastic films woven bags, and blow molding products. Whether you need to recycle PE films or rigid plastics (PE, PP, ABS, PA, PC), our twin-screw pelletizers provide an optimum performance, even for waste plastic with a high residual moisture content. The counter rotating twin screw increases the feeding process, while material with a small metal content will not slow the pelletizer down due to the unique twin screw design.

The screw diameter reaches 150mm. Compared to a conventional single screw extruder, our twin-screw extruder has a higher output capacity and is designed with parallel co-rotating for a modified plastic production.

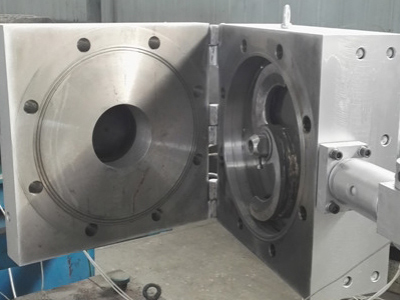

In addition, we supply water ring pelletizers and strand pelletizers to meet all your requirements for die face pelletizing and strand pelletizing. If needed, vertical dewatering machines with air blowers are also available for drying and conveying materials to the storage silo.

| Model | Screw Diameter | L/D | Screw Speed | Capacity (kg/h) |

| HS-50A | 50.5 | 28-60 | 400-600 | 120-280 |

| HS-50B | 50.5 | 28-60 | 400-600 | 120-280 |

| HS-52B | 51.4 | 28-60 | 400-600 | 225-375 |

| HS-52D | 51.4 | 28-60 | 400-600 | 150-380 |

| HS-65A | 62.4 | 28-60 | 400-600 | 200-500 |

| HS-65B | 62.4 | 28-60 | 400-600 | 350-600 |

| HS-75B | 71 | 28-60 | 400-600 | 300-550 |

| HS-75D | 71 | 28-60 | 400-600 | 300-800 |

| HS-85B | 81 | 28-60 | 400-600 | 500-1000 |

| HS-95B | 93 | 28-60 | 400-600 | 750-1400 |

- The body is made of high-quality nitriding steel through a 140-hour nitriding treatment. The strong hardness (HV850—1000) and excellent wear resistance make it durable and safe.

- The screw is manufactured from 38CrMoA1A alloy steel, and nitrided for 72 hours under high temperature, ensuring a great hardness and wear resistance. Screw replacement generally occurs when pellet production reaches 2,000 tons.

- The output capacity reaches 0.6 - 0.8 tons per hour.

- Compared to a single screw extruder, the twin-screw extruder has lower energy consumption.

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com