- Home

- products

- Pelletizing System

- Plastic Pelletizing System with Continuous Melt Filter

Plastic Pelletizing System with Continuous Melt Filter

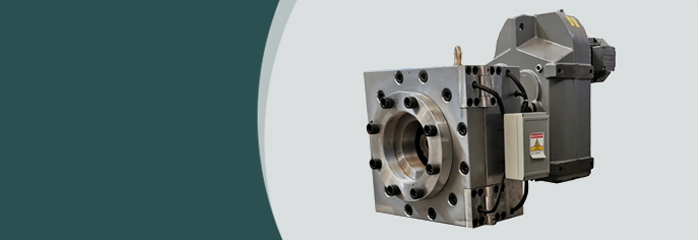

Haosu designs and manufactures plastic pelletizers with continuous melt filters that are guaranteed to have a long service life and long periods between filter changes, resulting in a low labor cost and a high output capacity.

Applications

Our plastic pelletizers with continuous melt filters can process a wide range of plastic materials including PP, PE, ABS, PS, and PA.

Specifications:

| Model | Diameter(mm) | Length(mm) | Power (kw) | Output (kg/h) |

| HS-100 | 100 | 2800 | 30 | 200 |

| HS-110 | 110 | 3200 | 37 | 250 |

| HS-120 | 120 | 3200 | 45 | 300 |

| HS-130 | 130 | 3200 | 55 | 350 |

| HS-140 | 140 | 3800 | 75 | 400 |

| HS-150 | 150 | 4200 | 90 | 500 |

Features:

- Fully automatic, continuous operation.

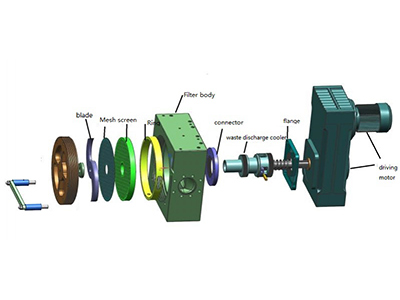

- Mesh number: 20 - 80

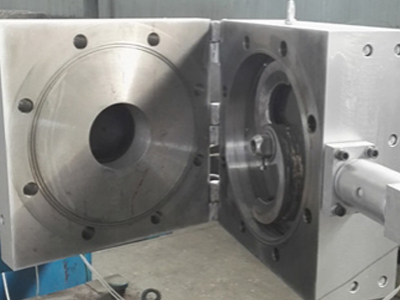

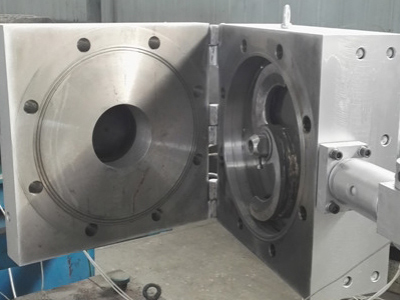

- Material: the durable body is made of P20 die steel and is strong enough to withstand high temperatures during the melting process.

- S shape knife: tungsten steel and hard alloy are used for the wearing knife.

- Automatically controlled via pressure sensors, this system will regularly filter and discharge unexpected residues.

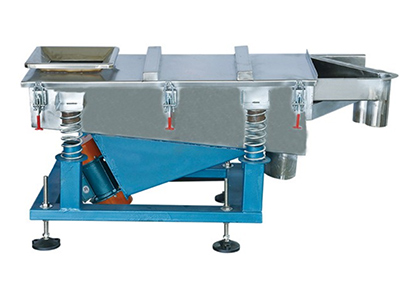

Shown here are a few previously produced water ring pelletizers. For special requirements, please do not hesitate to contact us.

Cases Study:

Our factory has over 30 sets of CNC lathes in the production of plastic processing equipment, such as feeding sawing machine, CNC gantry machining center, CNC screw milling machine, CNC deep-hole boring machine, and cylindrical grinder. Meanwhile, with the adoption of more technologies into plastic recycling, CAD/CAM continues to grow in importance. Thus during the whole manufacturing process, our experienced engineers and technicians utilize CAD/CAM engineering approaches to optimize the entire operation. This allows us to supply high quality plastic machinery with optimal performance.

Contact us

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com

Inquiry

Related Products