- Home

- products

- Pelletizing System

- Water Ring Pelletizing - Die Face

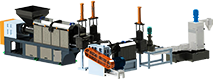

Water Ring Pelletizing System - Die Face

The water pelletizing system features a low energy consumption, easy startup and easy maintenance, making it an economical and effective HDPE and LDPE material pelletizing method.

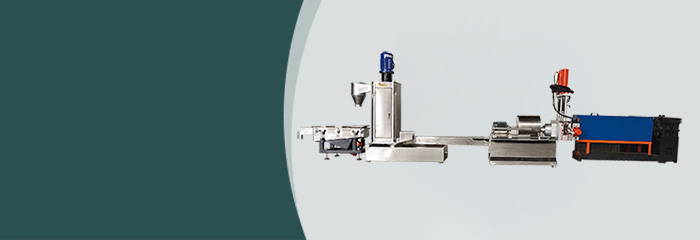

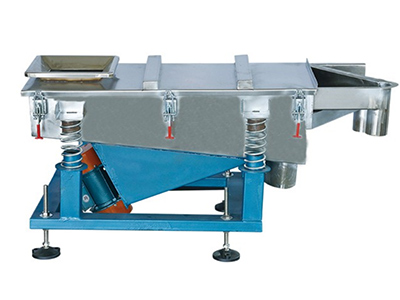

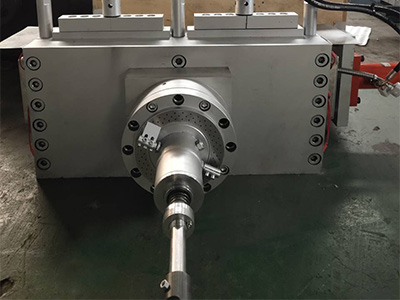

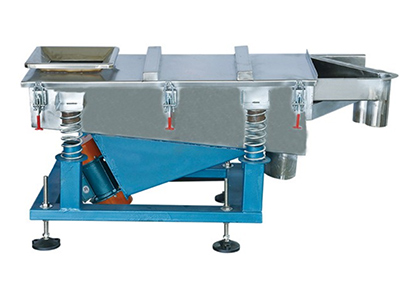

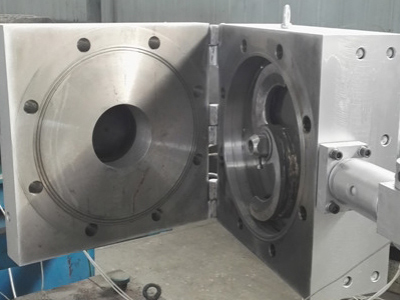

In the water ring pelletizing system, our pelletizers are used for processing molten plastic materials from extruders. They cut pellets using a hot die face, then throw the pellets into a water circulating cooling ring. The water ring pelletizing line consists of a two stage extruder, die head, adjustable knife seat, dewatering machine, vibrating separation screen and a storage silo.

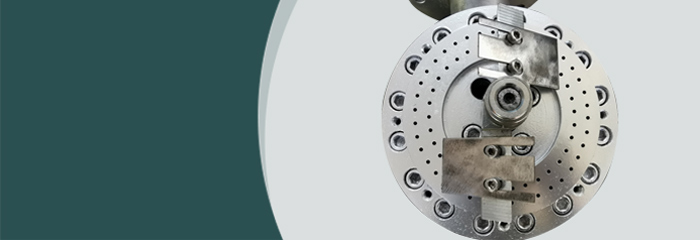

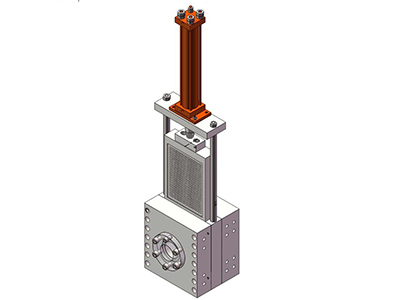

- The screen changer easily accommodates a variety of extruder centerline heights.

- Flexible cutting knives are easily adjusted with a variable speed digital drive. High speed knives cut pellets thinner.

- The cooling chamber achieves immediate quenching of pellets without any agglomeration.

- Electrical interlocks provide an effective operator protection.

- The molten plastic is cut off by rotating knives and cooled via a water circulating system. The result is cylindrical, dust-free pellets with excellent mixing properties that are convenient for packaging and transportation.

- The vibrating separation screen automatically sorts and removes coarse materials. It offers an additional convenience of an automated water ring pelletizing system.

Specifications:

| Model | Diameter(mm) | Length(mm) | Power(kw) | Output(kg/h) |

| HS-100 | 100 | 2800 | 30 | 200 |

| HS-110 | 110 | 3200 | 37 | 250 |

| HS-120 | 120 | 3200 | 45 | 300 |

| HS-130 | 130 | 3200 | 55 | 350 |

| HS-140 | 140 | 3800 | 75 | 400 |

| HS-150 | 150 | 4200 | 90 | 500 |

Specifications:

| Model | Diameter(mm) | Length(mm) | Power (kw) | Output(kg/h) |

| HS-160 | 160 | 2200 | 30 | 250 |

| HS-180 | 180 | 2600 | 55 | 300 |

| HS-200 | 200 | 3000 | 75 | 400 |

| HS-225 | 225 | 3200 | 90 | 500 |

| HS-260 | 260 | 3600 | 110 | 600 |

| HS-280 | 280 | 4000 | 132 | 800 |

Shown here are a few previously produced water ring pelletizers. For special requirements, please do not hesitate to contact us.

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com