Pelletizing System | Strand Extruder/Pelletizer, Water Ring Pelletizer

HS offers an extensive array of custom extrusion and pelletizing equipment to meet a variety of customer needs to produce high-quality, uniform pellets. Whether it is strand pelletizing or water ring pelletizing, complete systems or individual components, each of our pelletizing solutions is tailored to unique customer requirements.

-

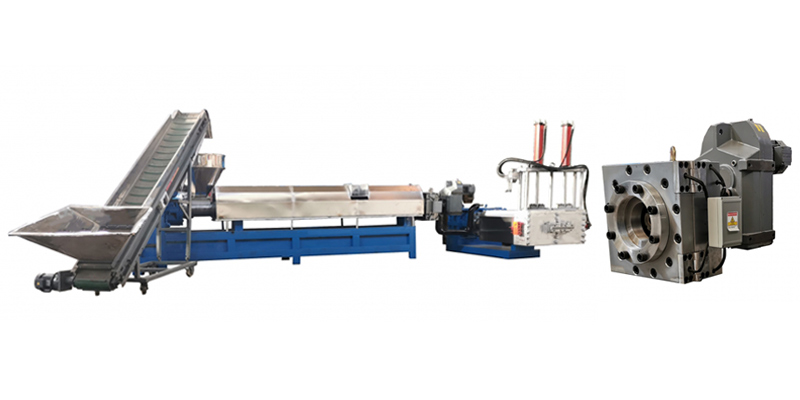

- Strand Pelletizing

- Haosu’s strand pelletizing systems offer a modern and economical method for pelletizing a wide range of plastic materials including HDPE, LDPE, PP, PET, PETP, ABS, PC, and PA, and works with more material types than a water ring pelletizing system can.

-

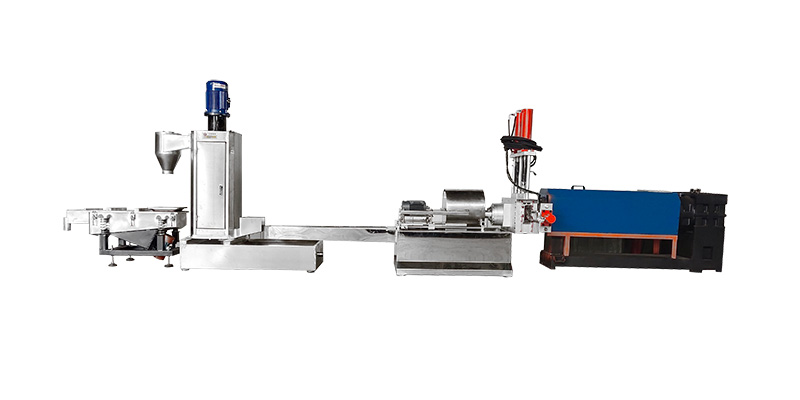

- Water Ring Pelletizing - Die Face

- The water pelletizing system features a low energy consumption, easy startup and easy maintenance, making it an economical and effective HDPE and LDPE material pelletizing method.

-

- Plastic Pelletizing System with Continuous Melt Filter

- Haosu designs and manufactures plastic pelletizers with continuous melt filters that are guaranteed to have a long service life and long periods between filter changes, resulting in a low labor cost and a high output capacity.

-

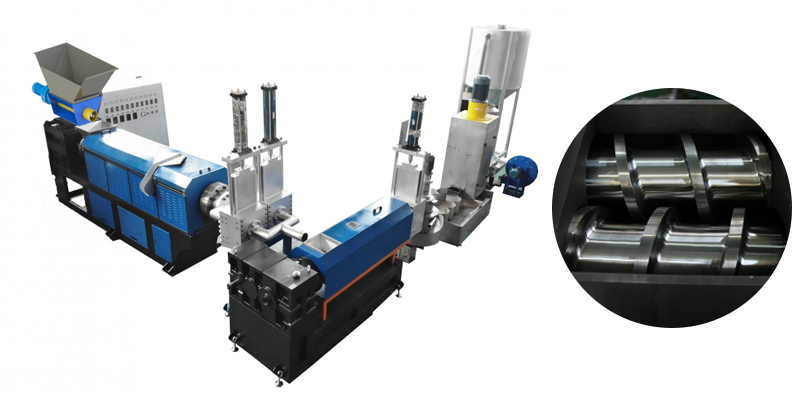

- Twin Screw Pelletizing

- To increase output capacity and improve pellet quality, Haosu designs and manufactures twin screw pelletizers for processing a wide variety of plastic materials such as plastic films woven bags, and blow molding products. Whether you need to recycle PE films or rigid plastics (PE, PP, ABS, PA, PC), ...

Custom plastic pelletizing system features:

- Additives are added for a better pellet quality during the pelletizing process.

- Masterbatches are used for colorful pellets.

- A wide selection of plastic extruders/pelletizers are available for two or three stage extrusion. The exact choice depends on the type of plastic material needing to be processed.

Our factory has over 30 sets of CNC lathes in the production of plastic processing equipment, such as feeding sawing machine, CNC gantry machining center, CNC screw milling machine, CNC deep-hole boring machine, and cylindrical grinder. Meanwhile, with the adoption of more technologies into plastic recycling, CAD/CAM continues to grow in importance. Thus during the whole manufacturing process, our experienced engineers and technicians utilize CAD/CAM engineering approaches to optimize the entire operation. This allows us to supply high quality plastic machinery with optimal performance.

Contact us

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com

Inquiry