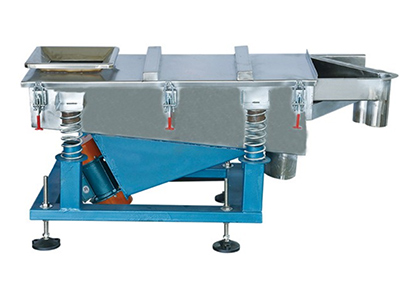

Non-ferrous metal separator for extracting metals from inert materials in plastic recycling plants

The magnetic separator can be used in conjunction with a variety of plastic recycling plant equipment. It removes scrap iron in the raw materials with the use of a magnet in the machine and ensures the plastic processing equipment is protected against damages caused by these iron scraps.

Parameters

| Type | Length(mm) | Height(mm) | Width(mm) | Power(W) |

| 7m | 3500 | 1900 | 360 | 400 |

| 8m | 4000 | 2200 | 360 | 400 |

| 9m | 4500 | 2500 | 360 | 1000 |

| 10m | 5000 | 3000 | 360 | 1500 |

Features

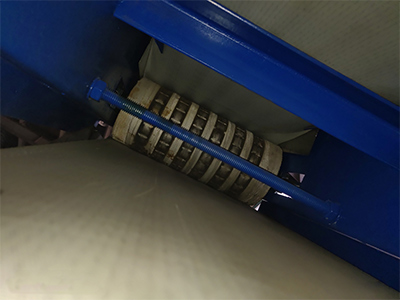

- The magnetic roller includes an extremely strong magnet with an excellent magnetism and iron removal performance.

- The belt is made of a high quality PVC material that features an excellent flexibility and long service life.

- Movable caster wheels are installed at the bottom to make machine movement easier.

Our factory has over 30 sets of CNC lathes in the production of plastic processing equipment, such as feeding sawing machine, CNC gantry machining center, CNC screw milling machine, CNC deep-hole boring machine, and cylindrical grinder. Meanwhile, with the adoption of more technologies into plastic recycling, CAD/CAM continues to grow in importance. Thus during the whole manufacturing process, our experienced engineers and technicians utilize CAD/CAM engineering approaches to optimize the entire operation. This allows us to supply high quality plastic machinery with optimal performance.

Contact us

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com

Inquiry

Related Products