- Home

- products

- Pelletizing System

- Strand Pelletizing

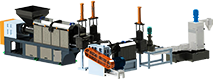

Strand Pelletizing System

Haosu’s strand pelletizing systems offer a modern and economical method for pelletizing a wide range of plastic materials including HDPE, LDPE, PP, PET, PETP, ABS, PC, and PA, and works with more material types than a water ring pelletizing system can. Our strand pelletizing systems are available as both wet and dry cut strand pelletizing equipment, producing the highest quality of cylindrical pellets or microgranular compounds ideal for further processing.

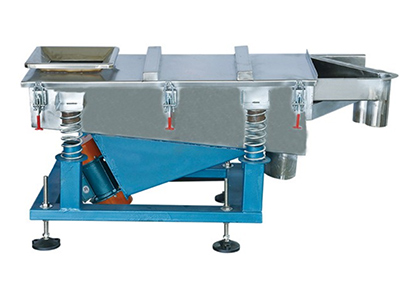

The strand pelletizing system typically consists of the extruder, cooling tank, pelletizer, screen machine, dryer and storage silo. We can design and manufacture the strand pelletizing systems with a throughput range of 100 kg/h to 1,200 kg/h.

The model configuration and technical specifications depend on the plastic type needing to be processed, while size and function of every component is individually tailored to your product needs. Based on specific plastic type and shapes, our technicians will work with you to determine the best strand pelletizing system with an optimal performance.

Specifications:

| Model | Diameter(mm) | Length(mm) | Power(kw) | Output(kg/h) |

| HS-100 | 100 | 2800 | 30 | 200 |

| HS-110 | 110 | 3200 | 37 | 250 |

| HS-120 | 120 | 3200 | 45 | 300 |

| HS-130 | 130 | 3200 | 55 | 350 |

| HS-140 | 140 | 3800 | 75 | 400 |

| HS-150 | 150 | 4200 | 90 | 500 |

Specifications:

| Model | Diameter(mm) | Length(mm) | Power(kw) | Output(kg/h) |

| HS-160 | 160 | 2200 | 30 | 250 |

| HS-180 | 180 | 2600 | 55 | 300 |

| HS-200 | 200 | 3000 | 75 | 400 |

| HS-225 | 225 | 3200 | 90 | 500 |

| HS-260 | 260 | 3600 | 110 | 600 |

| HS-280 | 280 | 4000 | 132 | 800 |

Shown here are previously made strand pelletizers. For special requirements, please do not hesitate to contact us.

Ningbo Haosu Machinery Co,. Ltd.

Add.: 691 Guanhai Road,Binhai Economic and Technological Development Area, Ningbo City, Zhejiang Province

Mobile: +86-13888623999

WhatsApp: +86-13967822787

E-mail: haosujixie@outlook.com